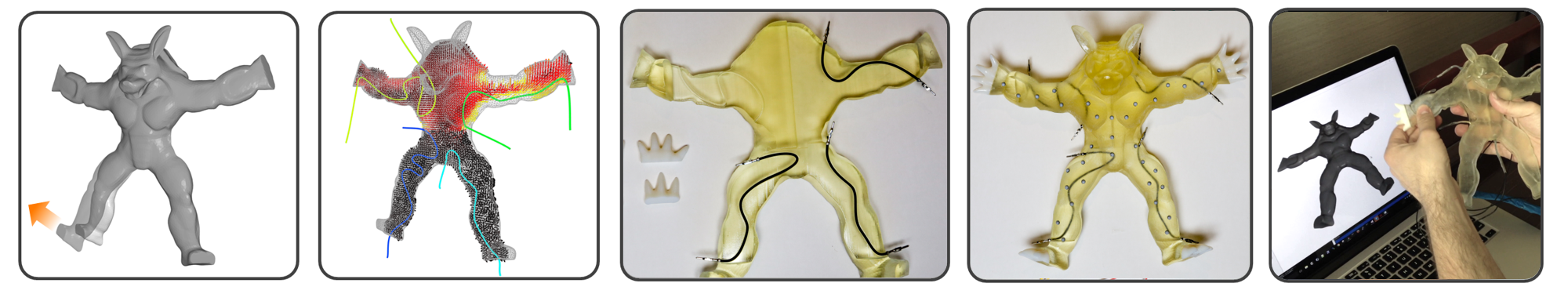

Design and fabrication of custom input devices (from left to right): the designer creates a set of example deformations (1) and roughly indicates where to place internal sensors. Our optimization algorithm then refines the sensor placement to maximize reconstruction accuracy (2). We fabricate our designs by inserting piezoresistive wires in-between 3D-printed body parts (3), then calibrate using motion capture (4). Our customized flexible input devices can be used in a variety of applications, e.g., to animate digital characters (5).

Abstract

We present a novel optimization-based algorithm for the design and fabrication of customized, deformable input devices, capable of continuously sensing their deformation. We propose to embed piezoresistive sensing elements into flexible 3D printed objects. These sensing elements are then utilized to recover rich and natural user interactions at runtime. Designing such objects manually is a challenging and hard problem for all but the simplest geometries and deformations. Our method simultaneously optimizes the internal routing of the sensing elements and computes a mapping from low-level sensor readings to user-specified outputs in order to minimize reconstruction error. We demonstrate the power and flexibility of the approach by designing and fabricating a set of flexible input devices. Our results indicate that the optimization-based design greatly outperforms manual routings in terms of reconstruction accuracy and thus interaction fidelity.

Video

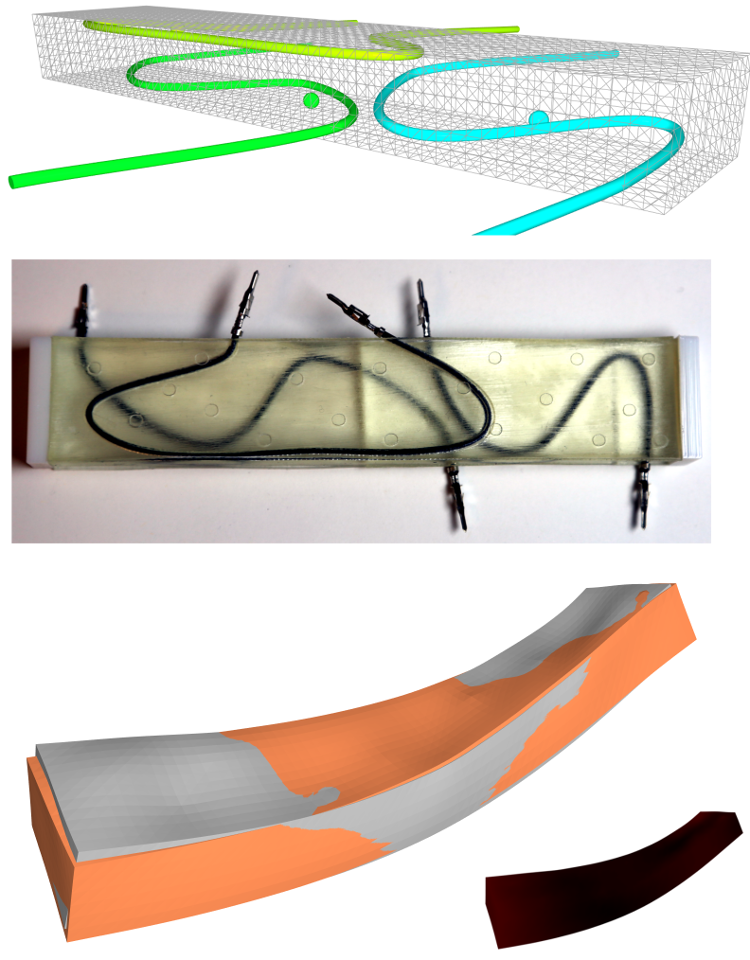

Gallery

Top row: schematic sensor routings obtained using our tool with automatic sensor refinement. Middle row: fabricated device. Bottom row: Ground truth (gray) vs. reconstruction (orange). Insets show error on a heat map scale, with maximum error (white) at 22 mm (darker is better).

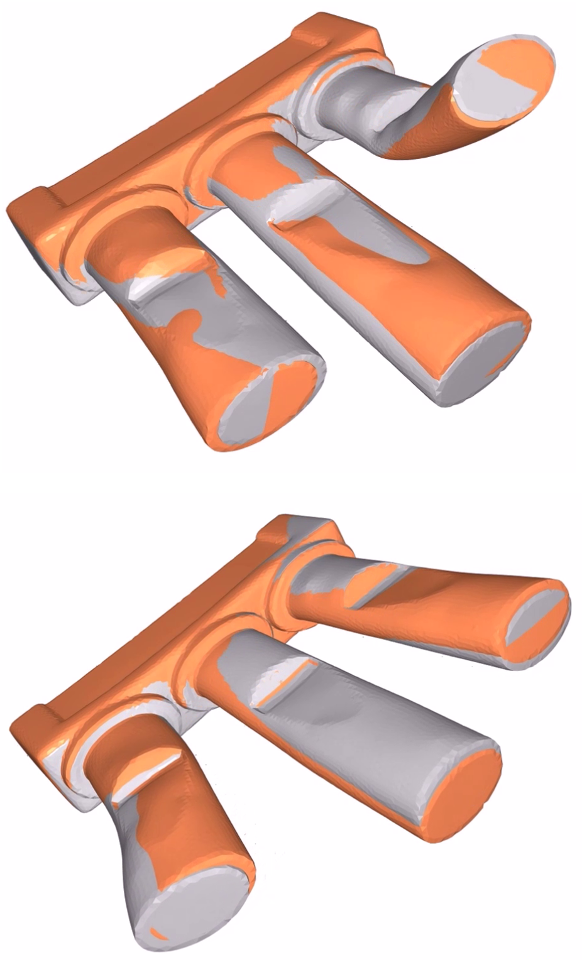

Two example deformations of the organ pipe model designed with our method. Ground truth (gray) vs. reconstruction (orange).

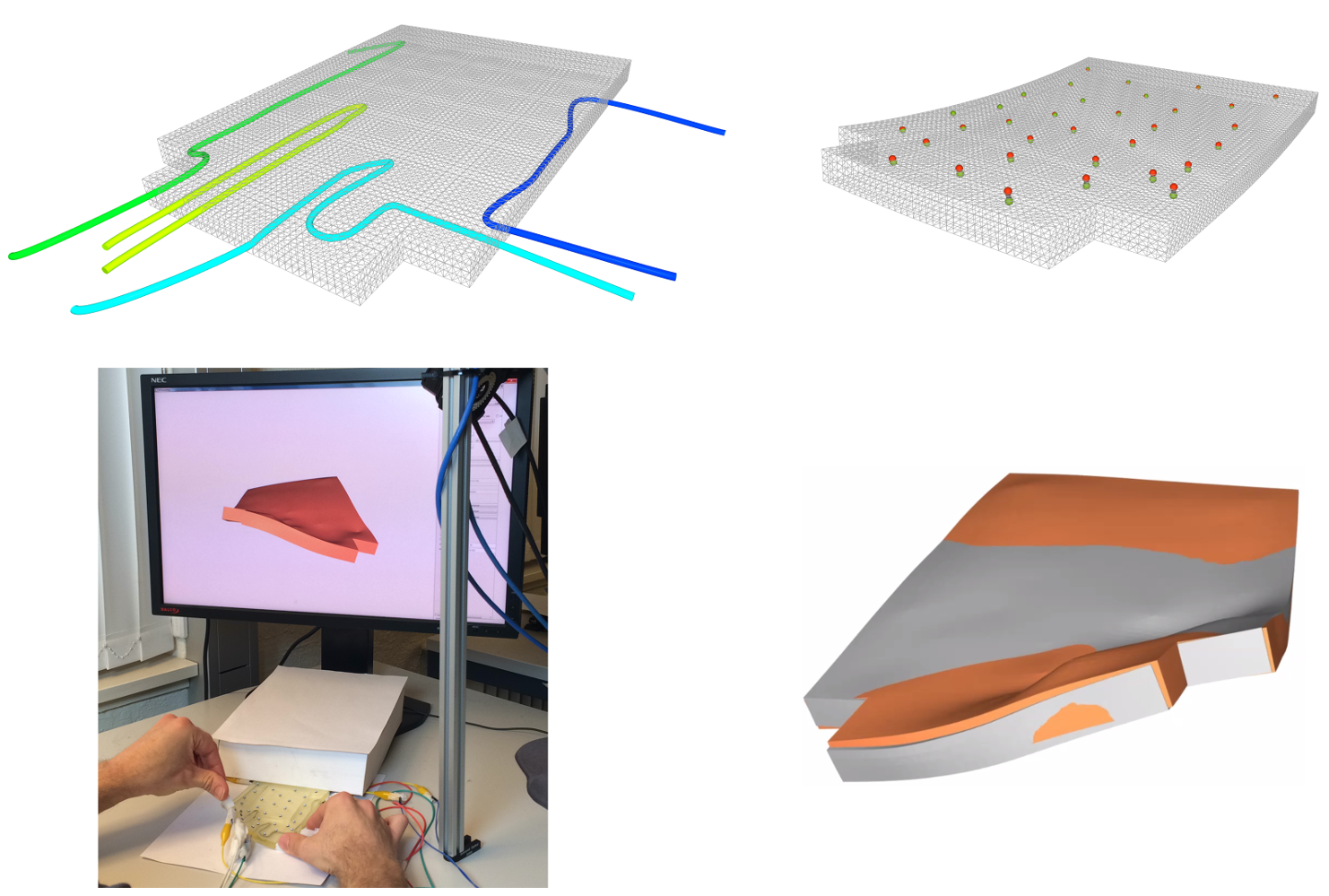

Snapshots of the design process. Top Row: the user placed, refined, and edited four sensors (left); Reconstruction error is expected to be very low (right). Bottom row: Interaction with fabricated device (left) and ground truth comparison (right).

Acknowledgments

We thank Damian Karrer, Rocco Ghielmini and Jemin Hwangbo for their help in our initial explorations. We would like to thank Christian Schumacher for creating the video and Cecile Edwards-Rietmann for providing the voiceover. Maurizio Nitti helped us in designing our 3D characters. We thank Chiara Daraio for insightful discussions on material properties and 3D printing. We also thank the CHI reviewers for their feedback and guidance. Fabrizio Pece was supported by an ETH/Marie Curie fellowship (FEL-3314-1).